Definition

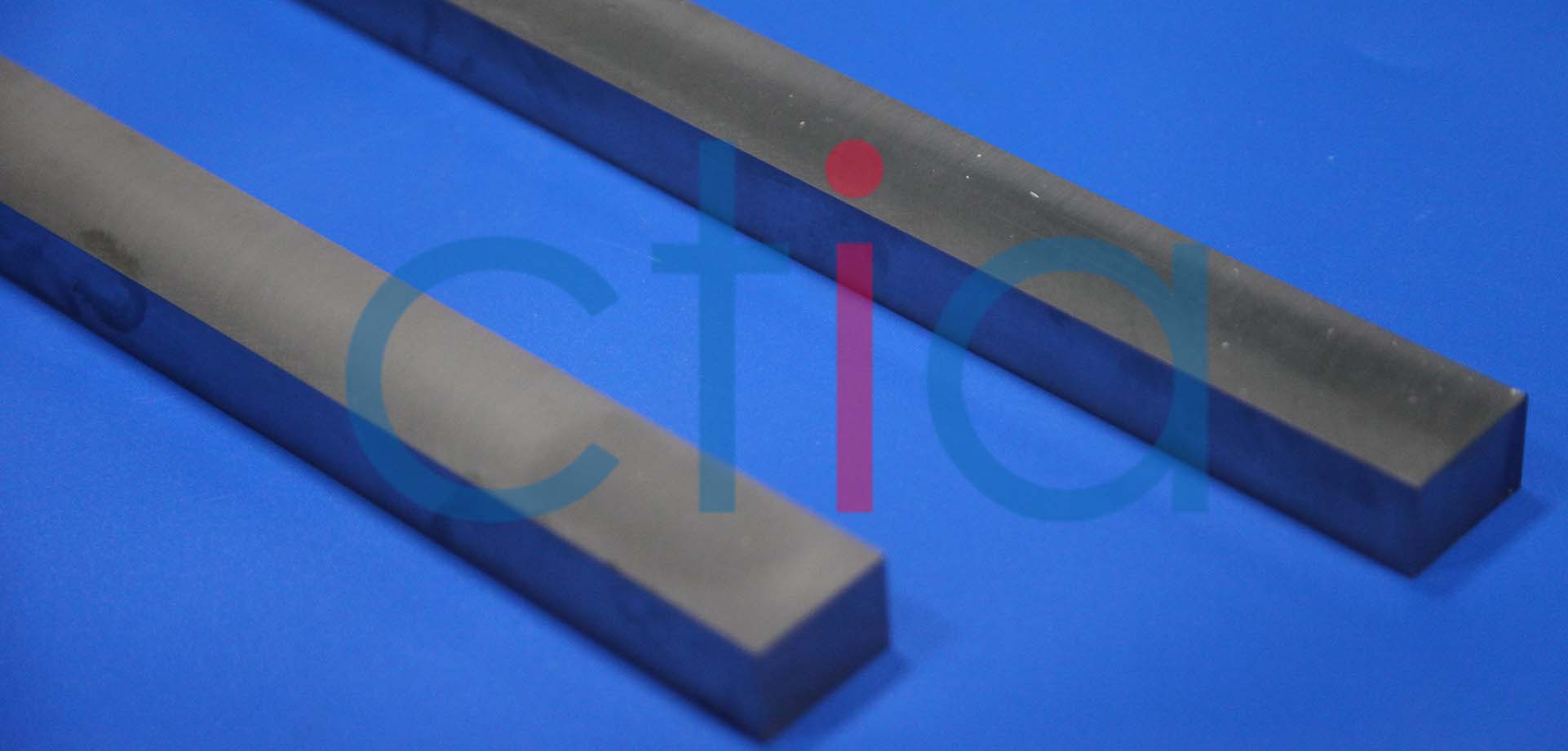

Tungsten alloy bar is high-density tungsten-based alloy products made primarily from tungsten (typically 90%–97%), alloyed with a certain proportion of nickel (Ni), iron (Fe), copper (Cu), and other metals through powder metallurgy processes. These bars are typically rectangular or square in shape and offer high strength, high density, and excellent machinability.

Key Properties

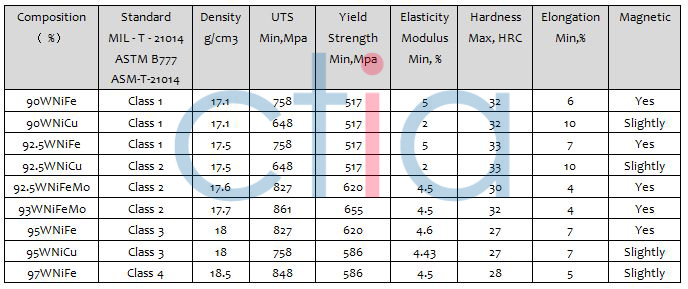

- High Density

With densities ranging from 17.0 to 18.5 g/cm³—more than twice that of ordinary steel—tungsten alloy bars are ideal for applications requiring compact counterweights or kinetic energy absorption. - Excellent Strength and Hardness

They feature high compressive strength and hardness, making them suitable for high-load or abrasive environments. - Outstanding High-Temperature Resistance

With a base tungsten melting point of up to 3410°C, the bars maintain strength and structural stability even under extreme heat. - Good Machinability

Optimized through alloying, they can be machined using conventional techniques such as turning, milling, and grinding. - Excellent Corrosion Resistance and Chemical Stability

They retain stability even in acidic or highly corrosive environments. - Low or Non-Magnetic (W-Ni-Cu system)

Suitable for use in magnetically sensitive applications such as medical imaging.

Common Types

- W-Ni-Fe Tungsten Alloy Bar

Well-balanced properties, commonly used in structural components and high-strength parts. - W-Ni-Cu Tungsten Alloy Bar

Low or non-magnetic type, ideal for environments such as MRI and medical devices. - High-Purity Tungsten Alloy Bar

Used in precision electronics and aerospace counterweights requiring ultra-high density and purity. - Military Armor-Piercing Tungsten Bar

Designed for kinetic energy penetrator cores with superior penetration capability.

Main Application Areas

- Aerospace Counterweights

Used in aircraft, satellites, and missiles as counterweight strips or dynamic balancing components. - Medical Shielding

For shielding bars and radiation protection components in X-ray and gamma-ray equipment. - Mold and Die Manufacturing

Used as wear-resistant tool bars, electrode strips, mold cores, and punches. - Electronics Industry

For electronic packaging materials, heat sink bars, and thermal management components. - Military Applications

Includes high-energy penetrator cores, tail fin weights for projectiles, and fire control counterweights. - Machinery Manufacturing

Suitable for high-inertia stamping parts and ultra-high-precision dynamic balancing parts.

Standard Specifications (Customizable)

- Cross-sectional Dimensions: e.g., 10×10 mm, 20×5 mm, 50×10 mm, etc.

- Length Range: 50 mm to 1000 mm (or per customer request)

- Density Grades: 17.0–18.5 g/cm³

- Surface Condition: As-sintered, turned, ground, or polished

- Machining Tolerances: Precision machining available per customer drawings

Machining & Delivery

Tungsten alloy bars can be provided with precision machining services including chamfering, drilling, tapping, and slotting. Surface treatments and inspection reports (e.g., density verification, ultrasonic flaw detection, mechanical property testing) are also available upon request.