- Product Definition

Tungsten alloy brick is high-density alloy blocks made from a high percentage of tungsten (typically over 90%), alloyed with elements such as nickel, iron, and copper, and sintered into rectangular or cubic shapes. They are primarily used in applications requiring compact volume with high mass or effective radiation shielding. These bricks feature robust structure, dimensional stability, and can be custom-made according to drawings.

- Key Properties

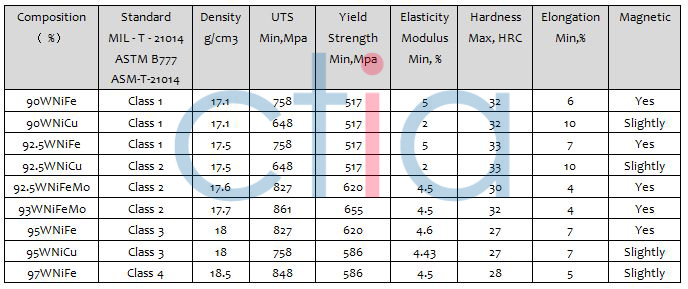

| Property Type | Specific Features |

| High Density | Density ranges from 17.0 to 18.8 g/cm³, much higher than lead and steel, enabling more compact designs. |

| Excellent Radiation Shielding | Superior shielding of gamma and X-rays compared to lead of the same volume, ideal for nuclear protection systems. |

| Good Mechanical Properties | High strength and rigidity, resistant to deformation, pressure, and wear. |

| Dimensional Stability | Low thermal expansion; maintains dimensional accuracy under high temperatures or stress. |

| Eco-Friendly & Safe | Free of radioactive elements, making it a green alternative to lead for radiation protection. |

- Common Types and Shapes

Standard Rectangular Brick

Example: 100×50×20 mm

Used in general counterweight and structural block applications.

Custom-Shaped Shielding Brick

Tailored to match equipment compartments, containers, or medical device geometry. May include grooves, holes, or interlocking features.

Stackable Modular Brick

Suitable for modular shielding in nuclear medicine or neutron protection setups.

Military-Grade Tungsten Brick

Applied in specialized protective structures such as armor layers, warhead shielding, or blast suppression systems.

- Major Application Areas

Nuclear Medicine & Radiation Therapy

Radiation shielding modules for medical accelerators, gamma knives, and X-ray machines

Linings for isotope transport containers and shielding blocks for high-activity radiation sources

Aerospace Counterweights

Inertial balancing blocks for satellites and aircraft

Control surface counterweights, mass adjustment bricks for propulsion systems

Military Defense Structures

Explosion protection systems, tail counterweights for armor-piercing projectiles

Muzzle device liners and inertial bricks in deceleration mechanisms

Industrial Counterweight Systems

High-precision mold counterweights

Anti-vibration components in precision instruments

Electronics and Thermal Management

Heat sink blocks for high-power devices

Inertial stabilization modules in microwave systems

- Specifications and Machining Capabilities (Customizable)

Size Range: Minimum 10×10×5 mm; maximum up to 500×300×100 mm

Density Options: 17.0 g/cm³, 17.5 g/cm³, 18.0 g/cm³, 18.5 g/cm³, etc.

Surface Finish: Ground, sandblasted, turned, or plated (e.g., nickel, silver)

Machining Tolerance: ±0.05 mm or as specified in drawings

- Delivery and Service Support

Support for custom design based on drawings and modular assembly

Available with ultrasonic flaw detection, density tests, and dimensional inspection reports

Capable of mass production and small batch prototyping

Environmentally compliant with RoHS, REACH, and other relevant certifications