I. Definition & Characteristics

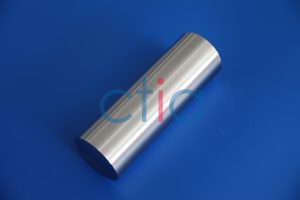

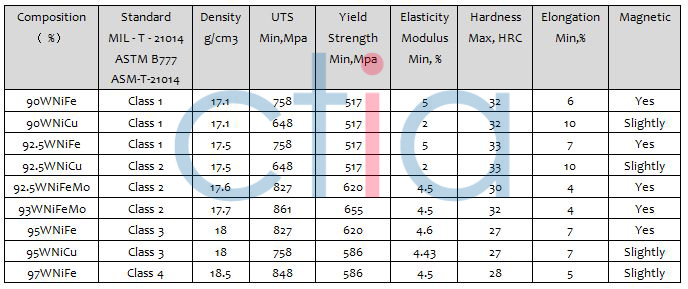

Tungsten alloy machined parts are custom components fabricated from high-density tungsten-based alloys such as W-Ni-Fe or W-Ni-Cu, using precision machining processes. Their key characteristics include:

- Extremely High Density: 17.0–18.5 g/cm³, allowing for compact, high-mass counterweights and kinetic energy control.

- Excellent Dimensional Stability: Minimal deformation under high temperature or mechanical stress; low thermal expansion coefficient.

- Good Machinability: Suitable for turning, milling, grinding, drilling, tapping, and other conventional machining operations.

- Customizable Complex Structures: Supports high-precision machining of both small precision components and large load-bearing parts.

- High Wear and Corrosion Resistance: Ideal for harsh operational environments.

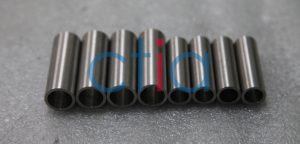

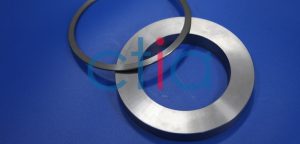

II.Common Types of Machined Parts

- Aerospace Counterweight Components

- Examples: Satellite module counterweights, inertia flywheels, missile center-of-gravity balancing blocks.

- Defense and Military Structural Parts

- Examples: Armor-piercing cores, tail fins, fire-control rotary parts, shock-absorbing blocks.

- Medical Radiation Shielding Parts

- Examples: CT/X-ray protection modules, isotope carriers, radiation shielding containers.

- Electronic Thermal Management Components

- Examples: Chip bases, heat sinks, precision brackets, and connector parts.

- Oil & Geological Exploration Components

- Examples: Logging tool counterweights, pressure-resistant probe housings, core components for drill bits.

- Molds & Mechanical Accessories

- Examples: High-inertia punches, electrode blocks, wear-resistant mold inserts, specialized fixtures.

III. Machining Capabilities

- Size Range: Capable of producing both micro-sized components and large complex shapes.

- Tolerance Grade: Precision tolerances up to ±0.01 mm or tighter upon request.

- Surface Treatment Options: Polishing, sandblasting, plating, passivation, etc.

- Complex Geometry: Supports hollowing, slots, threading, non-standard holes, and intricate structures.

- Drawing/Sample Customization: Fully integrated machining service based on customer drawings or samples.

IV. Technical Requirements & Considerations

- Material Properties Affect Machining: Tungsten alloys are hard and thermally conductive; carbide tools and low-speed, high-feed machining are recommended.

- Residual Stress Control: Proper heat treatment and machining path design help minimize internal stress and improve dimensional accuracy.

- Challenging Welding & Assembly: Due to poor weldability, mechanical fastening is typically used for assembly.

- Environmental & Safety Compliance: Tungsten alloys are non-radioactive and eco-friendly, making them suitable alternatives to traditional thorium-containing materials.

V. Application Examples

- Inertial Block for Aerospace: Φ45×30 mm, density 18.5 g/cm³, precision ±0.01 mm, surface roughness Ra 0.8.

- Medical Shielding Box: Internally machined cavity with threading, complex structure, high sealing performance.

- Projectile Core Component: Tapered composite structure with reinforced front tip for excellent penetration performance.

VI. Support Services

- Drawing conversion and design optimization

- Raw material and customer-supplied part machining

- Inspection reports (density, hardness, ultrasonic, dimensional)

- Prototyping and batch production services

© Copyright

The copyright of the article belongs to CTIA, please do not reprint without permission.

THE END

Like and Share