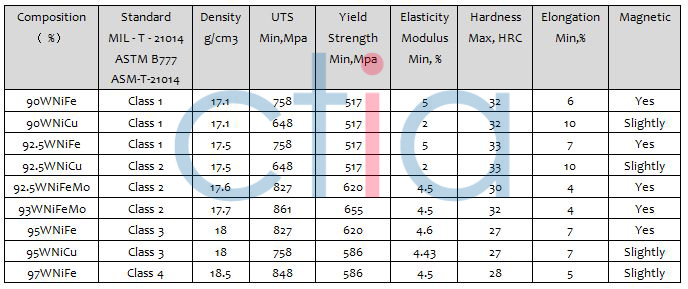

- Product Definition

Tungsten alloy sheet refers to metallic plate materials with a thickness less than 1.0 mm and relatively wide width, made from a tungsten-based alloy (typically containing over 90% tungsten), combined with elements such as nickel, iron, and copper. They are produced through hot isostatic pressing, hot rolling, and precision machining. These sheets offer high density, high strength, excellent heat resistance, and good machinability, making them ideal for applications requiring compact size, lightweight, and effective shielding.

- Key Performance Features

| Property | Description |

| High Density | 17.0–18.5 g/cm³, significantly higher than ordinary metal sheets; ideal for compact counterweights and protective structures. |

| Effective Radiation Shielding | Superior absorption of X-rays and gamma rays compared to lead of equal thickness; a non-toxic and eco-friendly alternative. |

| High-Temperature Resistance | Maintains strength and shape stability even above 2000°C. |

| Excellent Strength & Ductility | With Ni, Fe, or Cu added, the material achieves good formability and suitability for stamping. |

| High Chemical Stability | Oxidation and corrosion-resistant; maintains performance in harsh environments. |

| Environmentally Safe | Free of radioactive elements, suitable for replacing thorium tungsten or lead in medical and electronic applications. |

- Typical Specification Range (Customizable)

Thickness Range: 0.05 mm to 1.0 mm

Width Range: Up to 300 mm (wider widths customizable)

Length Range: Up to 1000 mm, or cut/leveled per customer drawings

Density Options: 17.0 to 18.5 g/cm³ selectable based on application

Surface Treatment: Pickled, bright surface, sandblasted, polished, or plated (e.g., nickel, gold plating)

- Common Types

- W-Ni-Fe Tungsten Alloy Sheet: Balances strength and ductility; widely used in electronics and industrial applications.

- W-Ni-Cu Non-Magnetic Tungsten Sheet: Ideal for use in low-magnetic environments such as medical imaging and MRI equipment.

- High-Purity Tungsten Sheet (W ≥ 99.95%): Mainly used for semiconductor equipment, vacuum coating targets, and thermal control structures.

- Typical Application Areas

- Electronics Industry

- Microelectronic packaging, chip heat sinks, electromagnetic shielding sheets

- Thermal conductive pads in microwave devices and RF modules

- Medical & Nuclear Shielding

- X-ray and gamma ray protective screens

- Isotope carriers or shielding sandwich materials

- Aerospace

- High-density counterweight plates in satellites and aircraft

- Thermal control plates and radiation shielding modules

- Precision Instruments & Watchmaking

- Balancing sheets, inertial adjustment components

- Micro-device counterweights

- Industrial Equipment

- Liner plates for high-temperature molds

- High-load anti-vibration plates and bullet-resistant panel inserts

- Processing & Delivery Capabilities

Cutting Services: Supports laser cutting, waterjet cutting, stamping, and other custom cutting methods

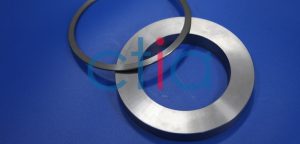

Custom Shapes: Can be machined into strips, flakes, rings, bent structures, etc., according to drawings

Dimensional Tolerance: Thickness tolerance up to ±0.01 mm; flatness better than 0.05 mm

Additional Services: Surface treatment, hole processing, protective film packaging, RoHS compliance reports, etc.