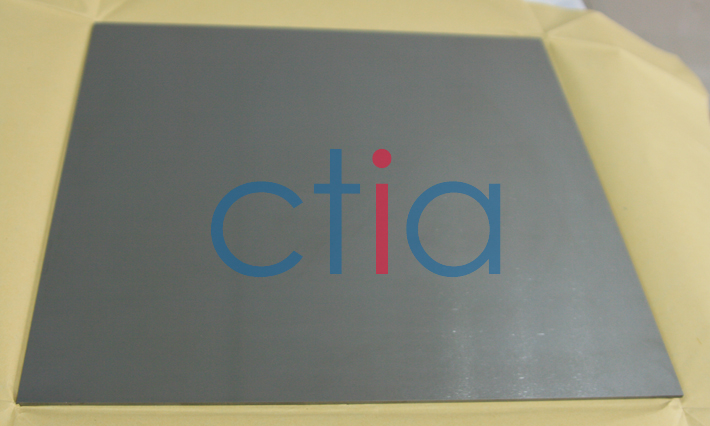

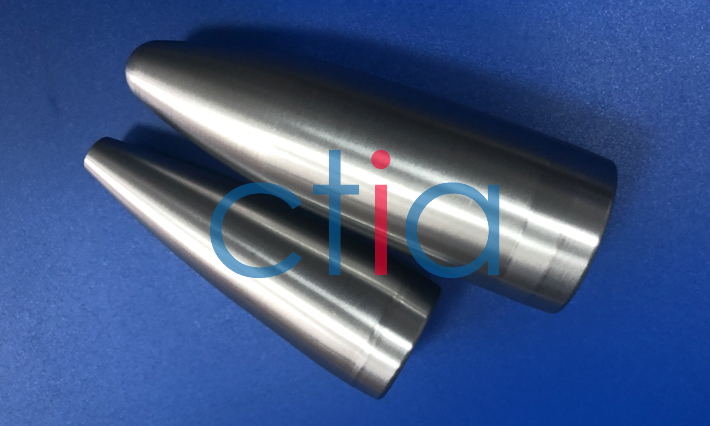

Molybdenum crucibles are made of high purity molybdenum powder, and using temperature is from 1100℃ to 1700℃. They are usually used in the metallurgical industry, rare earth industry, monocrystalline silicon, solar energy, artificial crystals and mechanical processing industries.

Corrosion resistance, creep resistance and high temperature characteristics make molybdenum crucibles very suitable for high temperature crystal growth processes. When sapphire is easy to extract, higher sapphire yield and quality can be achieved. The molybdenum-based crucible has heat resistance and a smooth surface, making it durable and cost-effective.

The surface roughness of the molybdenum crucible needs to be higher than 3.2 µm. When the surface of the crucible is rough, the sapphire is not easy to take out and it is easy to damage the crystal. In addition, the crucible will be damaged in the process. Sapphire manufacturers can benefit from this product because it eliminates complex and expensive processes. In addition, the smooth surface is resistant to corrosion caused by aggressively molten sapphire. This function can extend the service life of reusable crucibles.

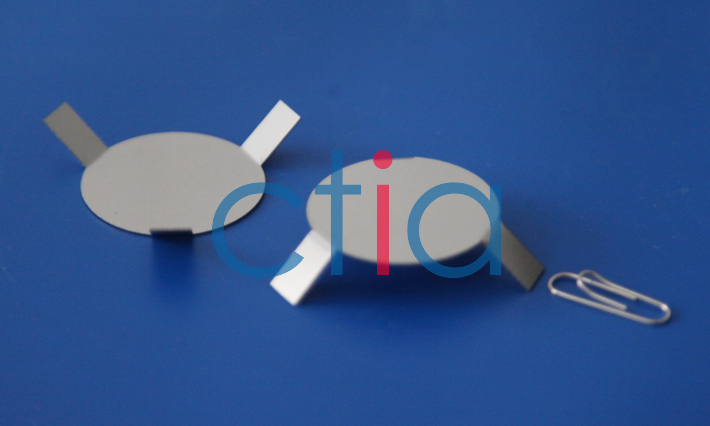

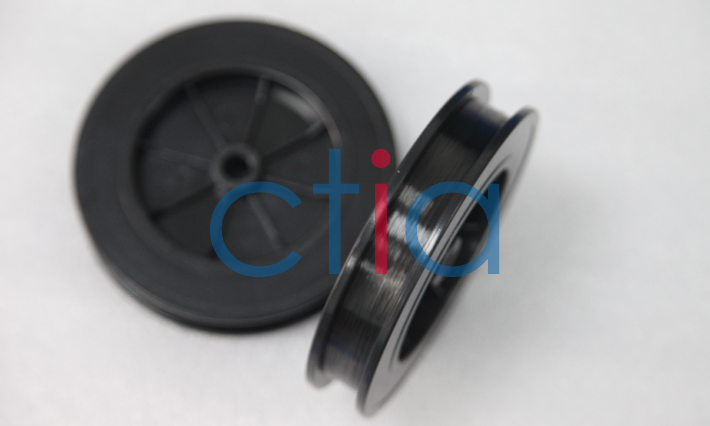

Crucibles are available with a variety of dimensions including round, in numerous standard diameters and wall thicknesses. Custom configurations are available. In addition, many other components for these furnaces are also customized.