Introduction

Tungsten alloy shielding parts are mainly used in medical and industrial fields. Compared with lead, it has the advantages of non-toxic, environmental protection, high density, small size and good shielding performance. Medical shielding parts mainly include radiotherapy shielding parts, multi-leaf gratings, isotope shielding containers for brachytherapy, radiation protection and collimation high-precision tungsten alloy parts, CT diagnostic shielding and collimating parts, shielding cans and collimating parts device. Industrial shielding components mainly include shielding walls, shielding windows, and radiation shielding covers for radioactive nuclear waste.

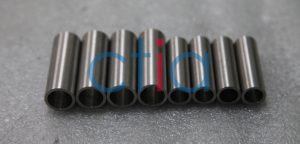

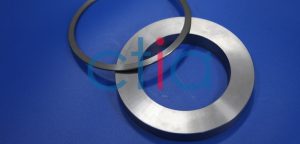

Basic Information

Density:17.0~18.75g/cm3

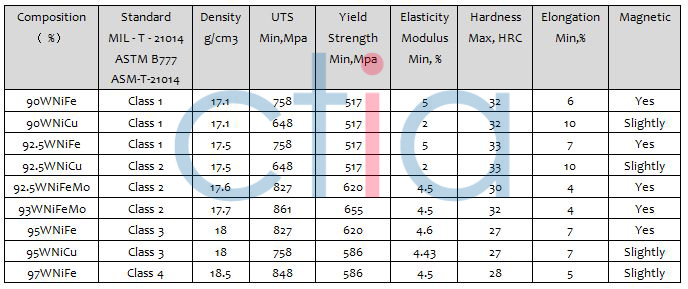

Component:90~97% WNiFe, WNiCu

Size: Can be customized

Advantages

High density and small volume: Compared with lead shields of the same weight, the volume of tungsten alloy shields is only 1/3 that of lead.

Absorbing radiation ability: The ability of high-density alloy to absorb radiation is 30%~40% higher than that of lead, and its stability is also better than lead.

Abrasion Resistance: Extends service life and saves time and cost by using tungsten alloy shielding cans.

Thermal conductivity: its thermal conductivity is 5 times than die steel.

Low coefficient of linear expansion: its coefficient of linear expansion is only 1/2~1/3 of that of iron or steel.

Ease of machining: The cutting of tungsten alloy is relatively easy to achieve, which provides the feasibility of designing multi-specification, complex size, and tungsten alloy counterweight bars.

Environmental protection: non-toxic and pollution-free, gradually replacing lead.