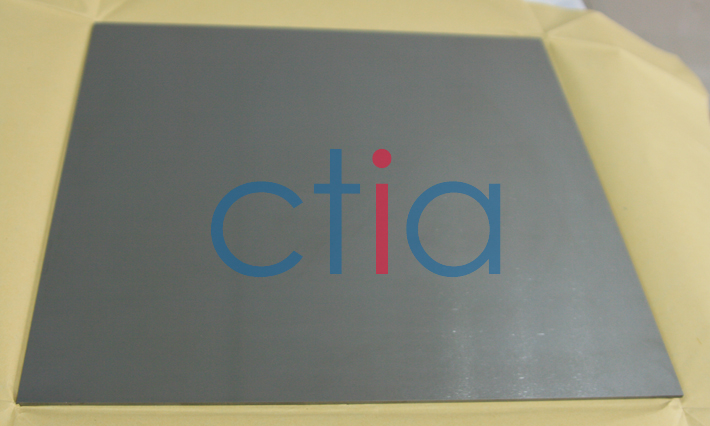

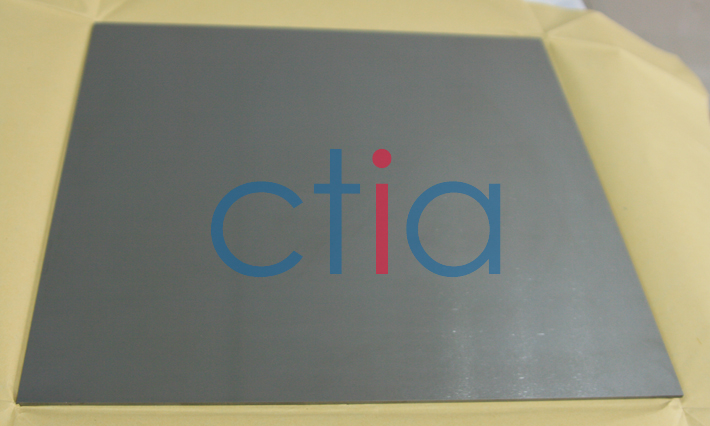

Titanium-Zirconium-Molybdenum (TZM) plate is a thin plate made from molybdenum alloy material. It is formed by hot rolling procedures and is polished further with different finishes depending on the applications.

TZM plate has more stable crystal structure and higher recrystallization temperature due to the doping of small amounts of zirconium and titanium into the molybdenum matrix. In addition, the composite carbides Mo2C, TiC, and ZrC with extremely fine sizes refine and suppress the grains of molybdenum, thereby contributing to the easier welding and creep resistance of TZM than pure molybdenum.

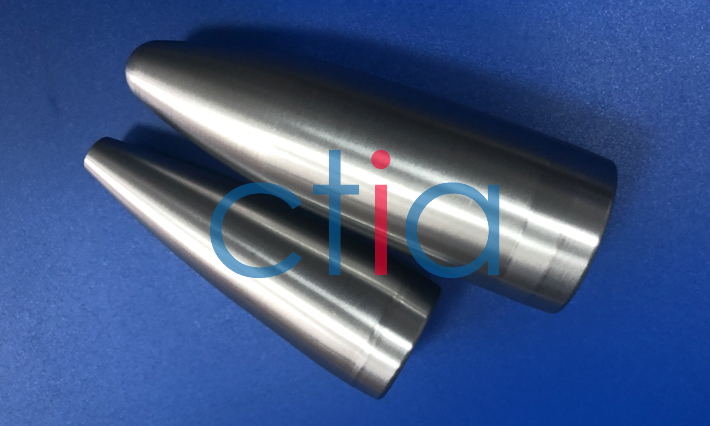

High temperature TZM plate is a popular molybdenum-based alloy used in structural furnace components such as shielding and support components because of its high creep resistance. In addition, TZM molybdenum plates are ideal for making high temperature, high strength TZM molybdenum forging dies for isothermal forging, ferrous and non-ferrous metal castings and molybdenum TZM perforated plugs. Additionally, this plate is an excellent choice for high recrystallisation and solderable temperature materials used to produce parts for aerospace applications.