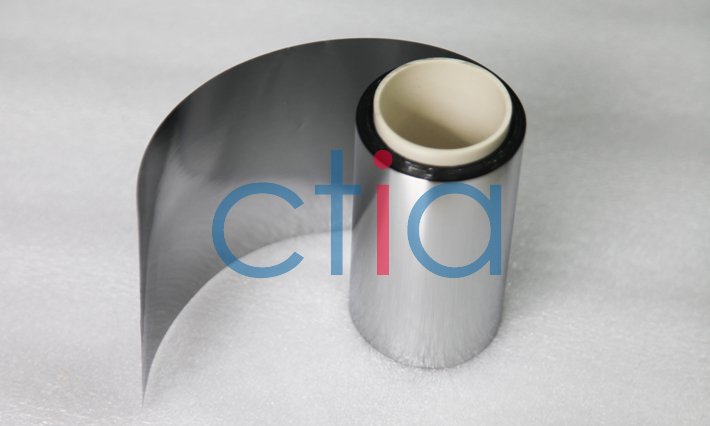

Introduction

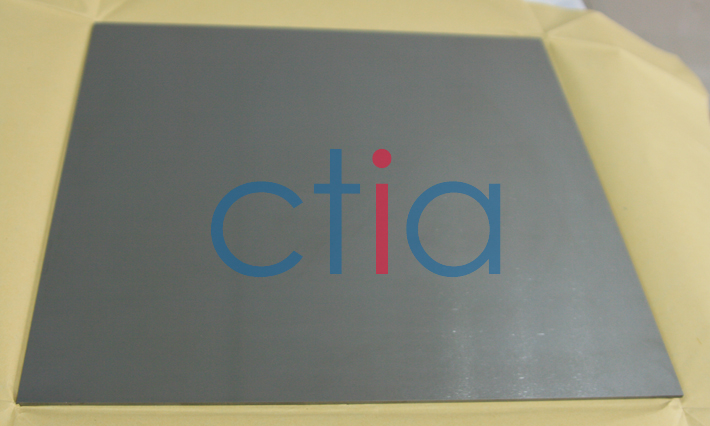

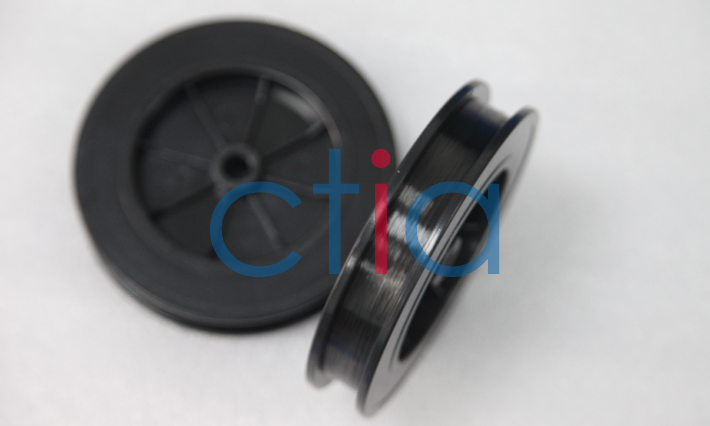

TZM, also known as titanium zirconium molybdenum, is a mature molybdenum alloy. This alloy is an attractive molybdenum-based alloy (0.4-0.54% Ti, 0.06-0.12 %Zr, 0.01-0.04% C, balance Mo) utilized in industries with high strength, high temperature and vacuum requirements, including aerospace, electronics and heat treatment.

Characteristics

Compared with pure molybdenum, TZM alloy has a more stable crystal structure and a higher recrystallization temperature. This is due to the small amount of zirconium and titanium doped in the molybdenum substrate. In addition, the extremely fine-sized composite carbides Mo2C, TiC and ZrC refine and suppress the molybdenum grains, so that alloy has better weldability and creep resistance than the pure molybdenum.

Applications

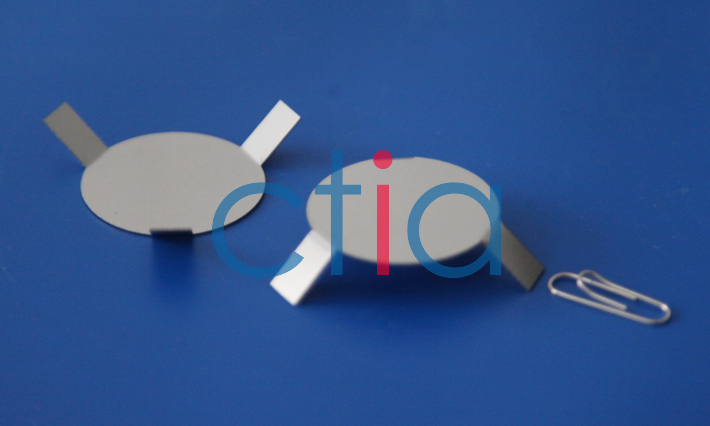

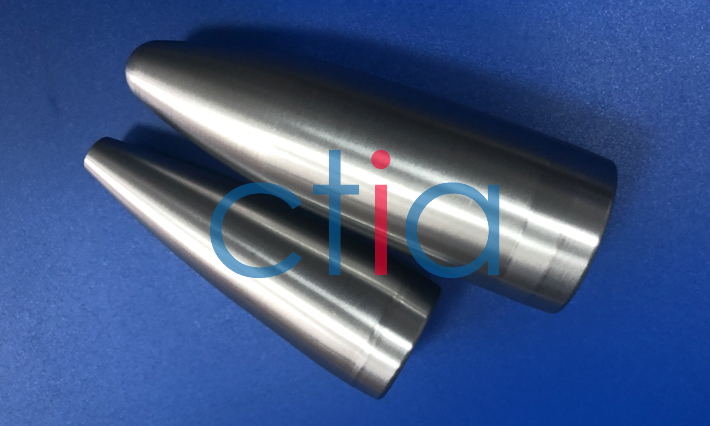

TZM rods can be used in some important applications including structural furnace components, die inserts for casting aluminum, rotating anodes for X-ray tubes, hot stamping tooling, rocket nozzles and electrodes. In addition to general use and its use in industry, they have many more applications and are also found in the field of military use. Torpedo engines are the best example of TZM alloys in military applications. This alloy is used in rocket nozzles, valve bodies, nozzle throats and gas pipes. In addition, TZM rod can also be used for hot runner systems for various type hot runner and hot runner nozzle production.