Lanthanated tungsten electrodes (La₂O₃-W electrodes) are non-radioactive tungsten electrodes made by doping high-purity tungsten with 0.8% to 2.2% lanthanum oxide (La₂O₃). As a high-performance alternative to traditional radioactive thoriated tungsten electrodes (Th-W), they are widely used in inert gas welding processes such as TIG (Tungsten Inert Gas welding) and PAW (Plasma Arc Welding).

The addition of lanthanum oxide significantly improves the electrode’s electron emission capability, arc starting performance, and high-temperature stability, making it suitable for various welding current types and material conditions.

1.Key Properties

| Property | Description |

| Electron Emission Capability | Higher than pure tungsten and comparable to Th-W; features low arc ignition voltage and excellent arc stability |

| Thermionic Emission Coefficient | Higher than Th-W, enabling efficient arc initiation at lower temperatures |

| High-Temperature Stability | Lanthanum oxide resides at grain boundaries, inhibiting grain growth and enhancing creep resistance |

| Service Life | Longer lifespan under appropriate welding conditions compared to thoriated electrodes |

| Non-Radioactive | Safe and environmentally friendly; complies with health and safety standards |

| Versatile Compatibility | Suitable for both AC and DC welding, especially beneficial for automated welding systems |

2.Main Applications

Due to their excellent comprehensive performance, lanthanated tungsten electrodes are widely used in the following areas:

TIG Welding

Ideal for welding carbon steel, stainless steel, copper alloys, and nickel alloys;

Especially suitable for low-current precision welding and multi-layer welding;

Plasma Arc Welding and Cutting

Excellent shape retention under strong arc conditions;

Suitable for cutting thick materials and high-speed automated welding systems;

Aerospace and Nuclear Industries

Preferred in environments with strict radiation control due to non-radioactive nature;

Precision Manufacturing

Common in microelectronics, medical devices, and vacuum welding applications requiring high arc precision and electrode durability.

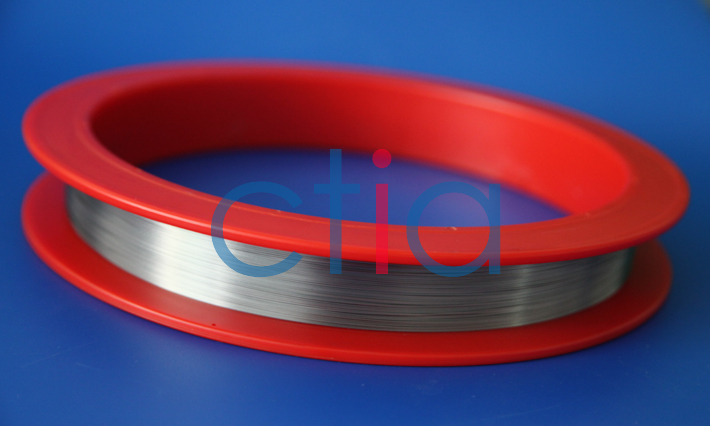

3.Types and Specifications

Lanthanated tungsten electrodes are commonly categorized by their lanthanum oxide content and color codes:

| Type | La₂O₃ Content | Color Code | Characteristics & Applications |

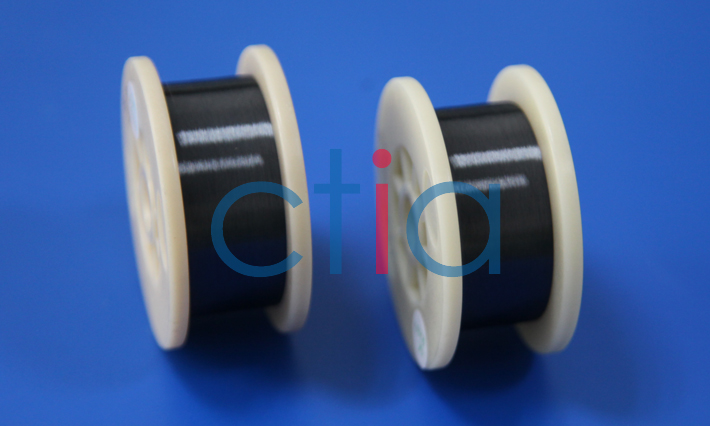

| WL10 | 0.8–1.2% | Black | Excellent arc-starting, suitable for AC/DC low-current applications; general purpose |

| WL15 | 1.3–1.7% | Gold | Similar performance to Th-W, stable arc and focused arc column; suitable for automated welding |

| WL20 | 1.8–2.2% | Sky Blue | High current capacity and longer service life at elevated temperatures; suitable for medium-to-high current welding |

4.Usage Recommendations and Precautions

Suitable for both AC and DC welding, with best performance under DC;

Sharpening the electrode tip before use is recommended for focused arc performance;

For AC welding of aluminum and magnesium, WL10 shows better arc stability;

If electrode tip erosion or contamination occurs, replace or resharpen promptly to ensure weld quality.