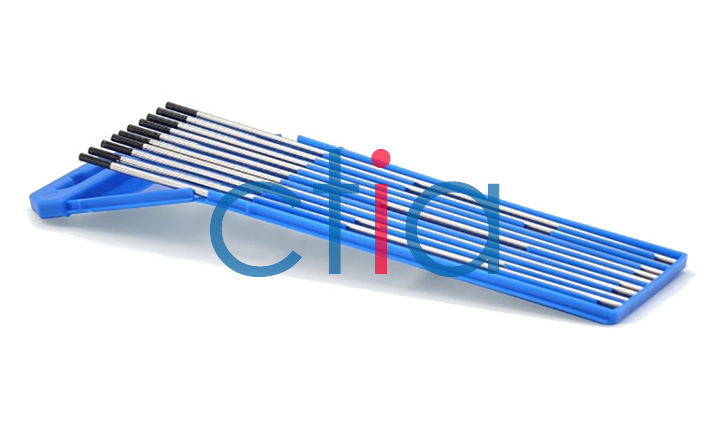

WL10 lanthanated tungsten electrodes (WL10 electrodes) are tungsten electrodes doped with 0.8%–1.2% lanthanum oxide (La₂O₃). Marked by the color black, WL10 is one of the most widely used non-radioactive and general-purpose tungsten electrodes. It offers a balance of arc-starting performance, thermal resistance, and arc stability.

Lanthanum oxide is uniformly distributed at the grain boundaries of the tungsten matrix, improving grain boundary structure, reducing grain growth, and enhancing resistance to arc erosion and high-temperature deformation.

1.Performance Characteristics

| Property | Technical Description |

| Arc Starting | Low arc-starting voltage, fast and stable ignition, comparable to thoriated tungsten |

| Current Capacity | Moderate; ideal for low to medium current operations |

| High-Temperature Resistance | Better arc erosion resistance than pure tungsten and cerium tungsten |

| Working Temperature | Operates stably at temperatures exceeding 2300°C |

| Contamination Resistance | Maintains tip shape; less prone to arc contamination and spattering |

| Sharpening Versatility | Can be ground into pointed or balled shapes; delivers focused arc |

| Radiation-Free | Safe and environmentally friendly; suitable for confined spaces and frequent handling |

2.Typical Applications

Thanks to its stable performance and versatility, WL10 electrodes are widely used in various welding and plasma processes:

Direct Current (DC) Welding

Suitable for welding stainless steel, carbon steel, copper alloys, titanium alloys, etc.

Performs especially well in automated welding and robotic welding systems

Ideal for thin sheets, tubes, and small parts requiring precision welding

Alternating Current (AC) Welding

Can be used for aluminum and magnesium welding under AC;

Outperforms pure tungsten in arc-starting and longevity;

Well-suited for square-wave and balanced AC power sources

Plasma Arc Processes (PAW, PAC)

Commonly used as the cathode in low-current plasma torches;

Performs well in automated, high-speed cutting and precision sealing applications

3.Usage Recommendations and Best Practices

Recommended Grinding Angle: 15°–30° conical point for concentrated arc focus

Optimal Current Range: 5A–200A under DC welding

Ideal for Continuous Welding: Especially in automated systems

Arc Starting Method: High-frequency ignition is preferred to avoid contamination

Maintenance: Replace or regrind the tip when heavy erosion or balling occurs

Storage: Store in dry, clean environments to prevent oxidation