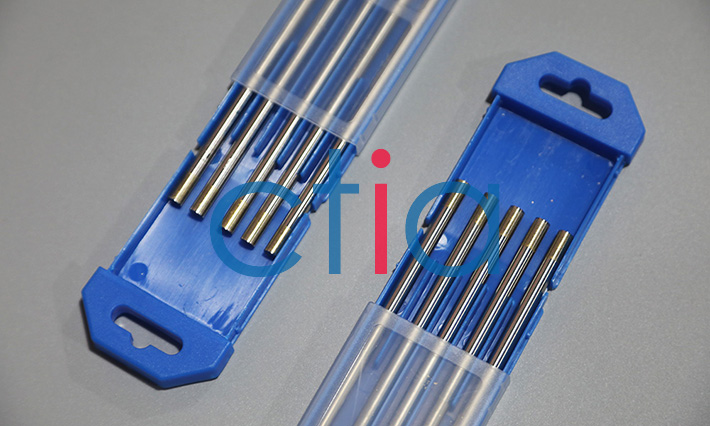

WL15 lanthanated tungsten electrodes (WL15 electrodes) contain 1.3%–1.7% lanthanum oxide (La₂O₃) and are marked with the color gold. As a medium-level doped electrode within the lanthanated tungsten family, WL15 offers outstanding arc-starting capability, arc stability, and erosion resistance. It is widely recognized as one of the best non-radioactive alternatives to thoriated tungsten electrodes (WT20).

WL15 combines the versatility of WL10 with the strength of WL20, making it especially suitable for high-frequency ignition, continuous welding, and automated welding systems. It is extensively used in high-demand sectors such as aerospace, nuclear, and precision manufacturing.

1.Key Performance Features

| Property | Description |

| Arc Starting Voltage | Extremely low; comparable to thoriated tungsten; ideal for high-frequency ignition |

| Arc Stability | Highly stable and focused arc; easy to control molten pool behavior |

| Arc Erosion Resistance | Better than WL10; maintains tip shape under load |

| Thermal Load Capacity | Handles medium to high currents without tip deformation or melting |

| Electrode Life | Comparable to or exceeds WT20 under proper welding conditions |

| Versatility | Suitable for AC, DC, and various base materials |

| Safety | Non-radioactive and compliant with international welding safety standards |

2.Primary Applications

Due to its balanced performance, WL15 is used in a wide range of applications, including:

Medium to High Current TIG Welding

Suitable for butt welding, fillet welding, and multi-pass welding

Commonly used for stainless steel, low alloy steel, copper alloys, nickel alloys, and titanium alloys

Automated Welding Systems

Stable arc and shape retention make it ideal for robotic welding

Frequently applied in automotive manufacturing, pressure vessel fabrication, and aerospace component welding

AC Welding (Aluminum and Magnesium)

Performs better than pure tungsten in AC waveform equipment

Offers longer lifespan and more stable arc characteristics for light metal welding

Plasma Welding and Precision Welding

Used as a cathode in plasma arc welding (PAW), particularly in applications requiring low penetration and high seal integrity

Common in medical devices, electronics, and precision assembly

3.Usage Recommendations and Best Practices

Recommended Grinding Angle: 25°–35° for optimal arc focus

Recommended Current Range: DC: 10A–300A; AC: 20A–250A

Compatible Power Sources: Best used with high-frequency ignition TIG machines

Ideal for Automation: Performs exceptionally well on automated tracks and robotic arms

Maintenance Tips: Inspect electrode tips after regular welding intervals; replace or regrind when signs of erosion or deformation are observed

Contamination Prevention: Avoid direct contact between the filler wire and the electrode tip to prevent contamination or oxidation