Introduction

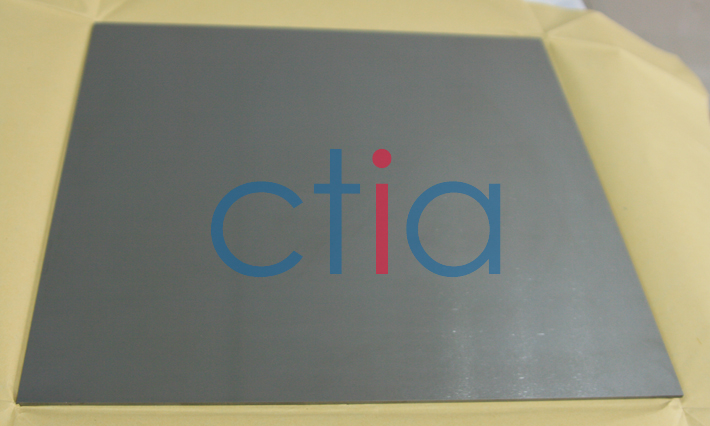

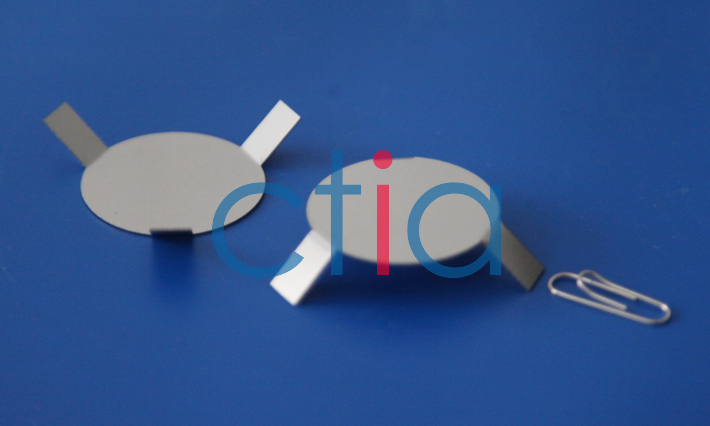

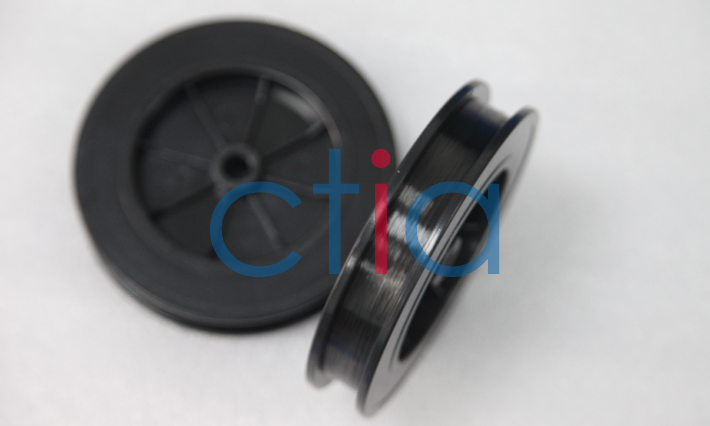

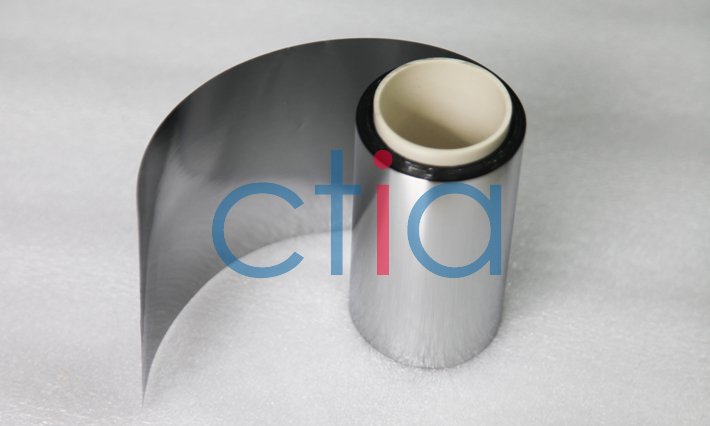

Molybdenum electrode is created by molybdenum material through powder metallurgy technology with very high purity and density to ensure the quality of finished glasses and the service life of electrode. The regular diameter ranges from 20mm to 155mm and the length can reach 1000mm or more, depending on the usage of clients. Usually, the electrode is machined with thread – outer thread or both outer and inner threads.

Characteristics

Molybdenum metal is an indispensable material in glass melting applications. Its unique chemical properties, metal properties, mechanical and physical properties enable manufactures to produce high-quality molybdenum electrodes for glass melting. The moly electrode does not chemically react with the molten glass, and does not cause staining to the molten glass. A small amount of molybdenum is dissolved as an oxide in the glass melt, which will make the soda lime glass slightly yellow, but it is usually very slight. Therefore, it has no effect even on colorless glass. The molten glass with poor reducibility has much less corrosive effect on it than the molten glass with oxidizing properties. In addition, the molybdenum component can also protect the refractory materials of the furnace from wear and corrosion, as a refractory brick that covers vulnerable areas as ‘armor’.

Applications

Mo electrode can be used for welding non-ferrous metals (copper, aluminum, nickel), such as copper braid for switches welding with metal sheet. And considering its high temperature strength, high temperature oxidation resistance, long service life, corrosion resistance and not easy to color glass, moly electrode is widely used in daily-use glass, optical glass, insulation materials, glass fiber, rare earth industry and other fields.