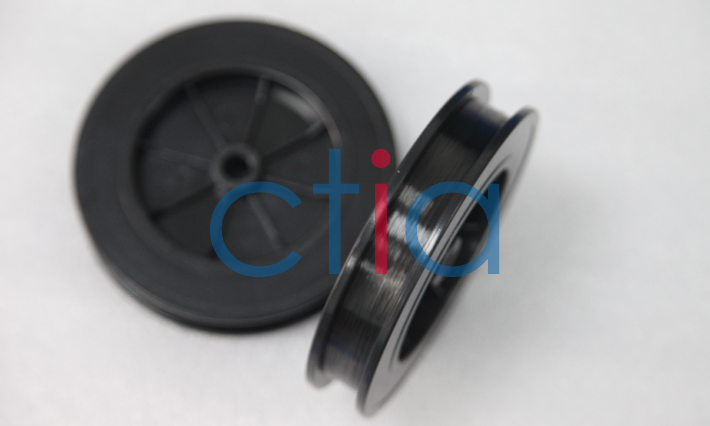

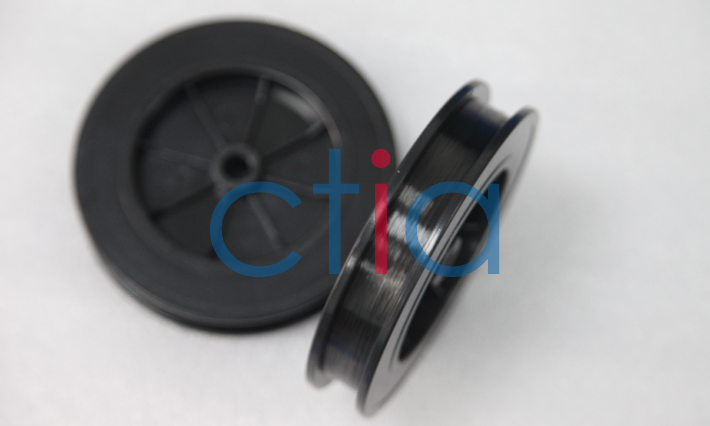

There are many types of molybdenum wires, including pure molybdenum wire, high-temperature molybdenum wire, molybdenum spray wire and molybdenum wire for EDM. Different types have different characteristics, and their uses are also different.

Pure molybdenum wire has high purity, and its surface is black. After alkali washing, it becomes white. With the characteristic of good electrical conductivity, it can be used as a part of light bulbs. For example, it is used to manufacture filament holders made of tungsten, lead wires for halogen bulbs, and electrodes for gas discharge lamps and tubes. This type of metal wire is also applied in aircraft windshields, where it acts as a heating element to provide defrosting function. In addition, it can be used to make electron tubes and power tube grids.

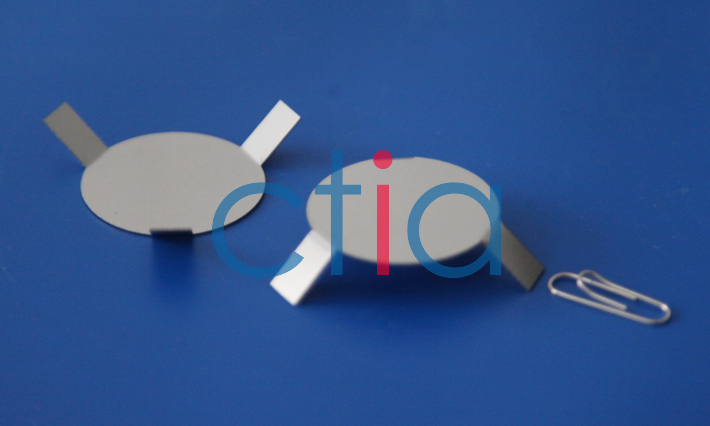

High-temperature molybdenum wire is also named molybdenum lanthanum wire. This molybdenum-based alloy is more popular than pure molybdenum because it has a higher recrystallization temperature, is stronger and more ductile after exposure to high temperatures. In addition, after being heated to above its recrystallization temperature and processed, the alloy forms an interlocking grain structure to help resist sagging and structural stability. Therefore, it is often used for high-temperature structural materials, such as printing pins, nuts and screws, halogen lamp holders, high-temperature furnace heating elements, and lead wires for quartz and high-temperature ceramic materials.

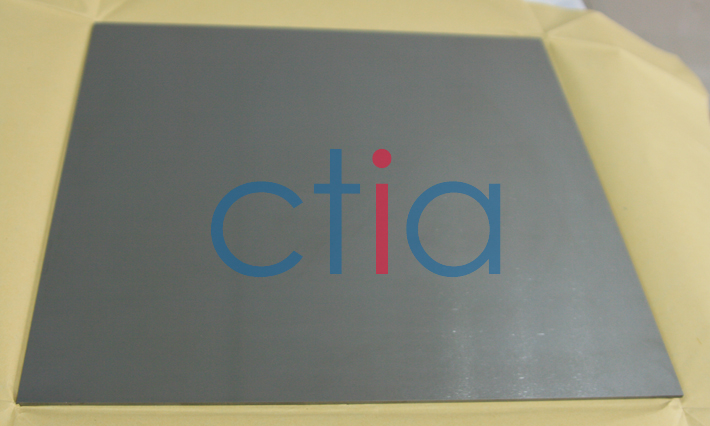

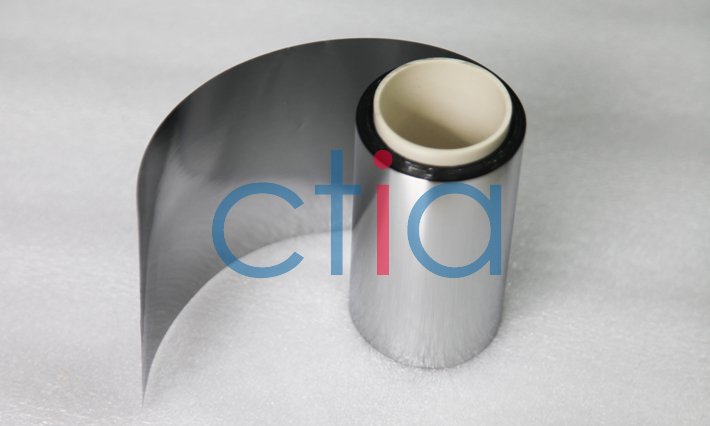

The molybdenum spray wire is mainly used for wear-prone automotive parts, such as piston rings, gearbox synchronization parts, gear selector forks, etc. A thin layer of coating is formed on the worn surface, which gives vehicles and parts good sliding properties coupled with excellent wear resistance.

While used for EDM, molybdenum wire can cut almost all conductive materials. This would include metals such as steel, aluminum, brass, titanium, and other types of aggregates and superalloys. The hardness of the material is not a factor in EDM machining.